HISTORY

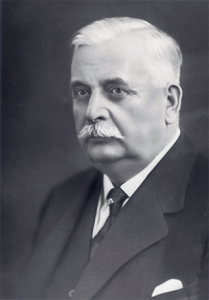

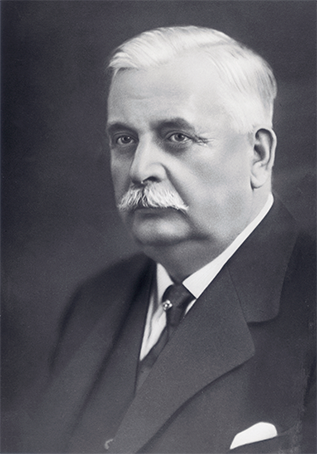

The story of ESAB is the story of welding. When our founder Oscar Kjellberg developed the world’s first coated welding electrode in 1904, he launched a company whose innovation and uncompromising standards have helped create the history of welding itself.

For more than 100 years, ESAB has been powered by the will to continuously seek new and improved ways of serving our customers. This has made ESAB a world leader in welding products and advanced cutting systems.

ESAB became a publicly traded, independent company under ESAB Corporation on April 5, 2022 following the spin-off from Colfax.

The foundation of ESAB was built early in the last century by an inventive engineer who sought a practical solution to a common problem.

In 1904, Oscar Kjellberg produced a heavily fluxed, or coated, electrode that substantially improved the quality of weld metal. As it melted, the flux coating vaporized and formed a gas that shielded the molten weld metal from air, thus preventing embrittling reactions from occurring as the weld metal cooled.

Lightly coated electrodes of various types had been tried before, and some of them permitted faster welding, but none of them improved the weld metal properties. Kjellberg was the first to recognize the possibilities of the heavy flux coating in preventing atmospheric contamination and is today recognized as the inventor of the coated electrode. To this day, tens of thousands of welders encounter his initials in the form of an OK on the welding consumables they use.

Since Kjellberg founded Elektriska Svetsnings-Aktiebolaget (ESAB) in Sweden in 1904, the company has led the welding industry in engineering and innovation, never losing sight of ESAB’s original mission to provide its customers the highest caliber of products and services.

Today’s ESAB is the result of a 1989 union of industry leaders: Alloy Rods Corporation, L-TEC Welding & Cutting Systems, All-State Welding Products, ESAB Automation and ESAB Welding Products. These companies represent more than 300 years of experience in welding consumables and equipment manufacturing, and have introduced many innovative products and processes, including stainless stick and low hydrogen electrodes, as well as submerged arc, TIG (“Heliarc”) and MIG welding.

1904: WELDING INVENTED

Swedish engineer Oscar Kjellberg develops the worlds first coated welding electrode and founds Elektriska Svetsnings-Aktiebolaget (ESAB).

1906: INNOVATION UNFOLDS

The patent is granted for Kjellberg’s unique invention – the world’s first coated welding electrode.

1913: FIRST REGULATOR INVENTED

Victor® brand founder, l. W. Stettner, develops the first piston regulator after losing his eye in a gas equipment accident, setting a new standard for safety.

1922: HARDFACING SOLUTIONS INTRODUCED

The Stoody brothers create the category of hardfacing welding products in Whittier, CA.

1936: GROUND CLAMP IMPROVED

Ray Townsend forms the Townsend Welding Equipment Company (Tweco®), introducing the now-synonymous “redhead” ground clamp as its first product.

1937: SAW INVENTED

Breakthrough development. The submerged arc welding (SAW) method is invented, providing a versatile means of depositing large amounts of metal quickly, consistently, and safely.

1944: TIG (HELIARC) INVENTED

Revolutionary technology. A new process of TIG welding (called Heliarc) is introduced, giving welders greater control over the weld for stronger, higher-quality results.

1949: CAC-A PROCESS INVENTED

Myron Stepath invents the CAC-A cutting and gouging process, founding Arcair® and introducing the G-3 cutting and gouging torch.

1950: GMAW INVENTED

Quantum leap. To this day, the versatility and speed of gas metal arc welding (GMAW) or MIG/ MAG welding makes it the most commonly used industrial welding process.

1955: PLASMA CUTTING INVENTED

The Linde division of Union Carbide invents the plasma arc for cutting metals. Linde later became L-tec, which was eventually acquired by ESAB.

1970: FIRST PAK INTRODUCED

Thermal Dynamics® introduces their pak unit-power supply, Pak 40, the first to combine the cooling system and the console into one unit.

1972: UNDERWATER TORCH INVENTED

Arcair, an ESAB company, develops and introduces the first underwater cutting and welding torch for the US Navy.

1980: EXOTHERMIC CUTTING INVENTED

The SLICE® torch is introduced, setting a new standard for portable and quick cutting solutions for fire and rescue operations.

1984: SMALL DIAMETER GAS SHIELDED WIRE INVENTED

Alloy rods, acquired by ESAB, develops a .035″ diameter gas-shielded cored wire for use on jobs previously restricted to solid wires or stick electrodes

1990: PARTS LIFE IMPROVED

Thermal Dynamics introduces hafnium inserts, allowing for longer-lasting oxygen and air-cutting solutions.

1993: A WELDING CONSUMABLES PIONEER

Marathon Pac, a unique bulk pack for solid or flux-cored welding wire, is introduced.

1995: OXY-FUEL TORCH SAFETY IMPROVED

Victor develops and integrates patented built-in flashback arrestors into their torches for added operator safety.

1996: FIRST OF ITS KIND

ESAB’s first friction-stir welding machine, SuperStir™, is supplied to Marine Aluminum of Norway.

2003: 1TORCH INTRODUCED

Thermal Dynamics’ dual-mode torch (1Torch) is developed, allowing it to be used on all portable air-cutting systems (contact start or high-voltage start).

2009: EDGE 1.0 INTRODUCED

Victor introduces the first generation of EDGE regulators, featuring the enhanced safety attributes of slam™ technology and an internal particle trap.

2010: HIGH SPEED SAW INVENTED

ESAB develops and introduces high-speed submerged arc welding (SAW) with ICE™, allowing for up to 50% higher deposition rates and significant productivity increases.

2012: NEXT GENERATION TECHNOLOGY

ICE™, the next generation in submerged arc welding technology, is advanced based on ESAB’s leading Twin subarc process.

2015: REBEL INTRODUCED

ESAB develops Rebel, a revolutionary multi-process weld system providing industrial-quality arc performance in a compact design.

2017: EDGE 2.0 INTRODUCED

Victor releases improved EDGE 2.0 regulators, building on the innovations of the original EDGE 1.0 to become the safest regulators in the world.

2018: REBEL 205 INTRODUCED

ESAB develops the world’s first truly all-process portable welding machine with MIG, flux cored, Stick, DC TIG, and AC TIG capabilities.

2018: DIGITAL SOLUTIONS INTRODUCED

ESAB launches its first digital applications designed to leverage data from users, assets and processes to improve business outcomes.

2020: ESAB OVERCOMES

When the world stopped during the COVID-19 pandemic, the industry kept moving forward. ESAB adjusted to the unprecedented times and continued to supply fabricators with innovative solutions while protecting the health and safety of employees.

2021: NETFLIX SERIES

ESAB made its Netflix debut in the reality competition series “Metal Shop Masters” as the sole provider of welding equipment.

2022: ESAB CORPORATION

In 2022 the ESAB Corporation opened its new headquarters in North Bethesda, MD, a collaborative environment as innovative and technology-forward as our products and solutions. Our new space includes nods to our global footprint and the different industries ESAB Corporation serves.

From the firsts by our founder to our global growth, we take pride in what we’ve accomplished in a century and a decade. But we do so with a keen eye on the next 110 years. What can we do better? It’s only when we seek to build upon all we’ve learned, to perfect the innovations our customers count on to work confidently, to push ourselves and our company further that we can boldly face the future. This is how we continue to write the history of welding and cutting. Because at the end of the day, it’s not where you’ve been that matters most – but where you’re going. And for us, that’s forward.

With 110 years of innovation under our belts, we’re looking to further shape the future of welding and cutting — starting now.